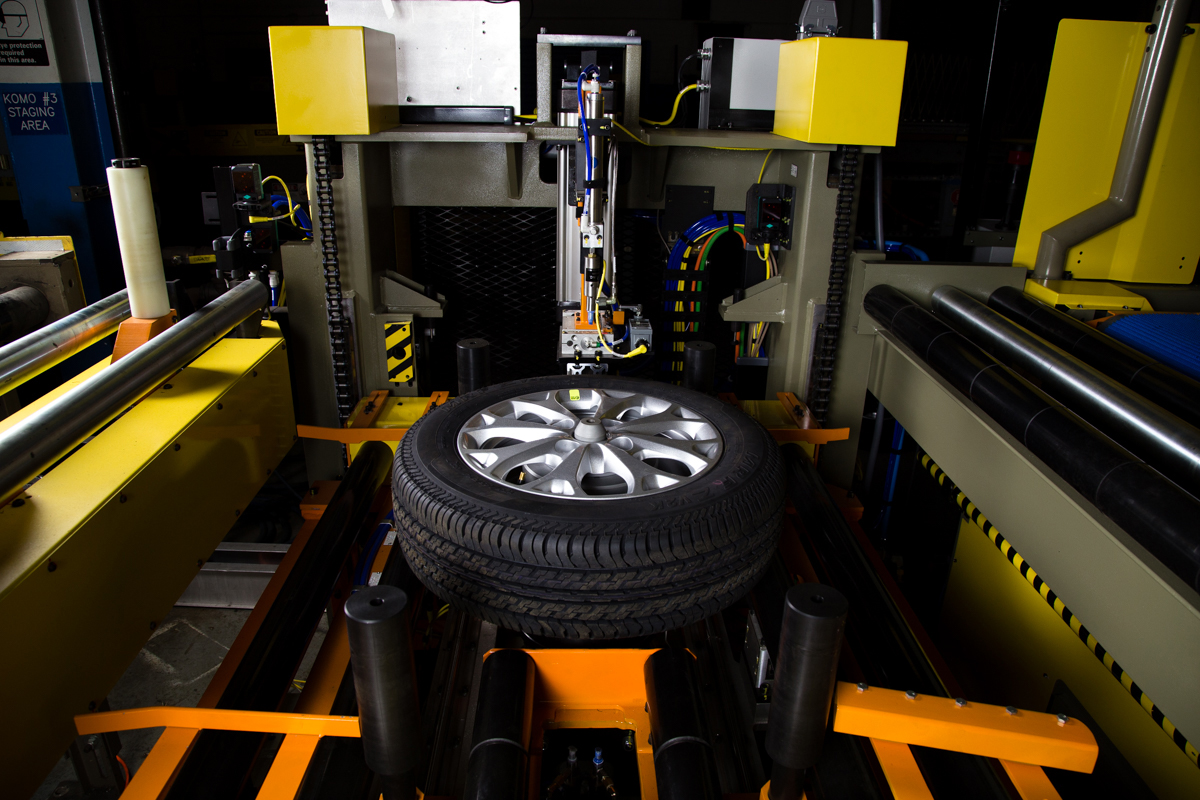

Balancer

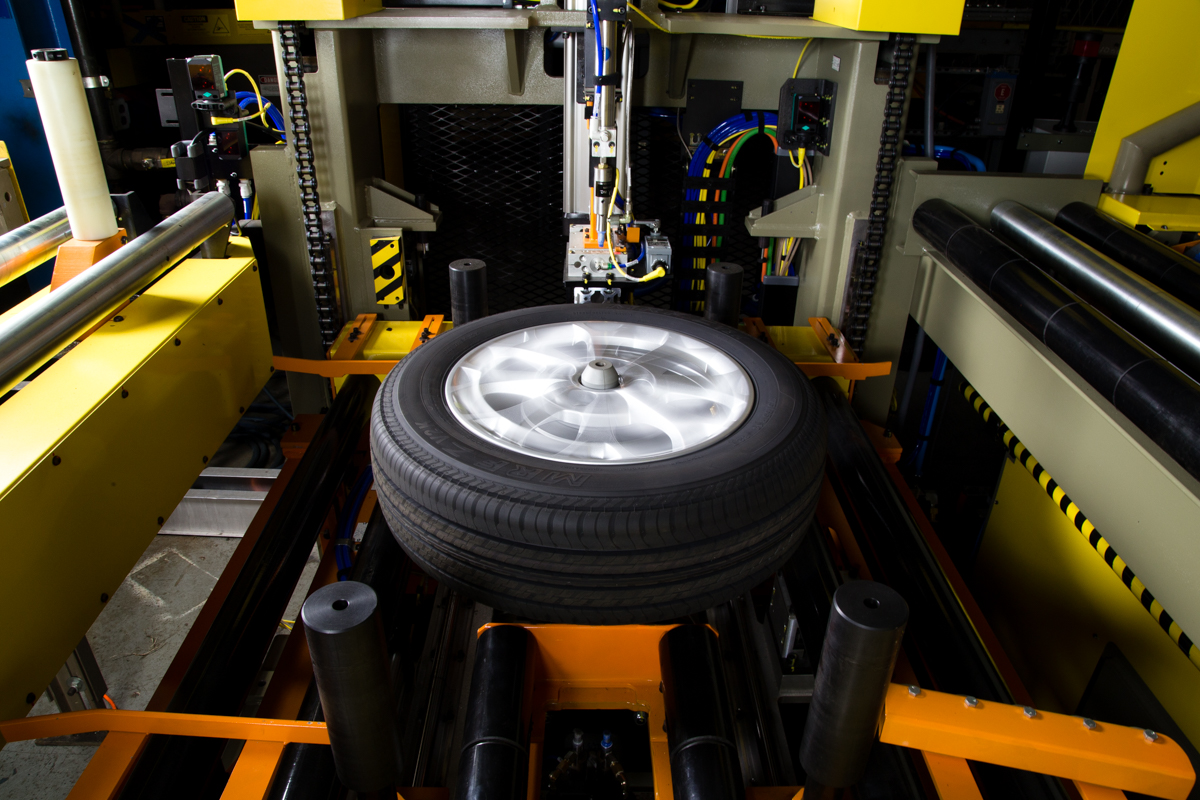

Dominion's Tire Assembly Balancer is designed for high production application in automotive assembly plants. It also can be provided as a component of the complete tire room or as a stand-alone station for simple integration into our customer's process.

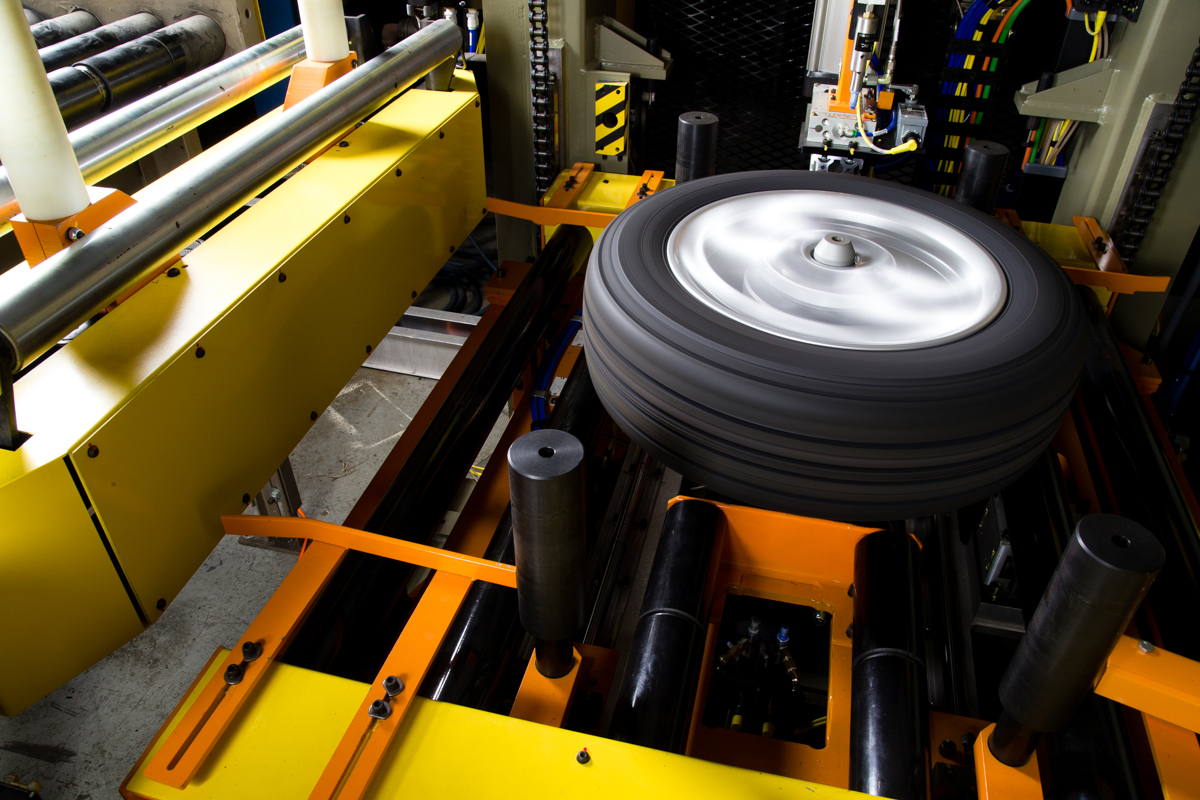

Vibration isolators allow for simple installation without the requirement of foundation isolation.

The unitized design of the Balancer simplifies preventative maintenance and service functions.

The Tire Assembly Balancer is a single-station dynamic balancer. The Balancer can be configured as a Primary, an Audit or a Balance-Audit machine. The system uses a Programmable Logic Controller (PLC) for all of the machine functions and a Windows-based computer for all of the test and data storage functions.

Features

- Unitized design for ease of service and prevetative maintenance

- Seamless integration with Dominion Vision for plant broadcast

- Capable of Passenger/Light Truck/Low Aspect Ration Assemblies

Add-Ons

- Tooling Options

- Multiple jaw chuck capable of handling variable bore diameters

- Collet design for applications that have a common bore

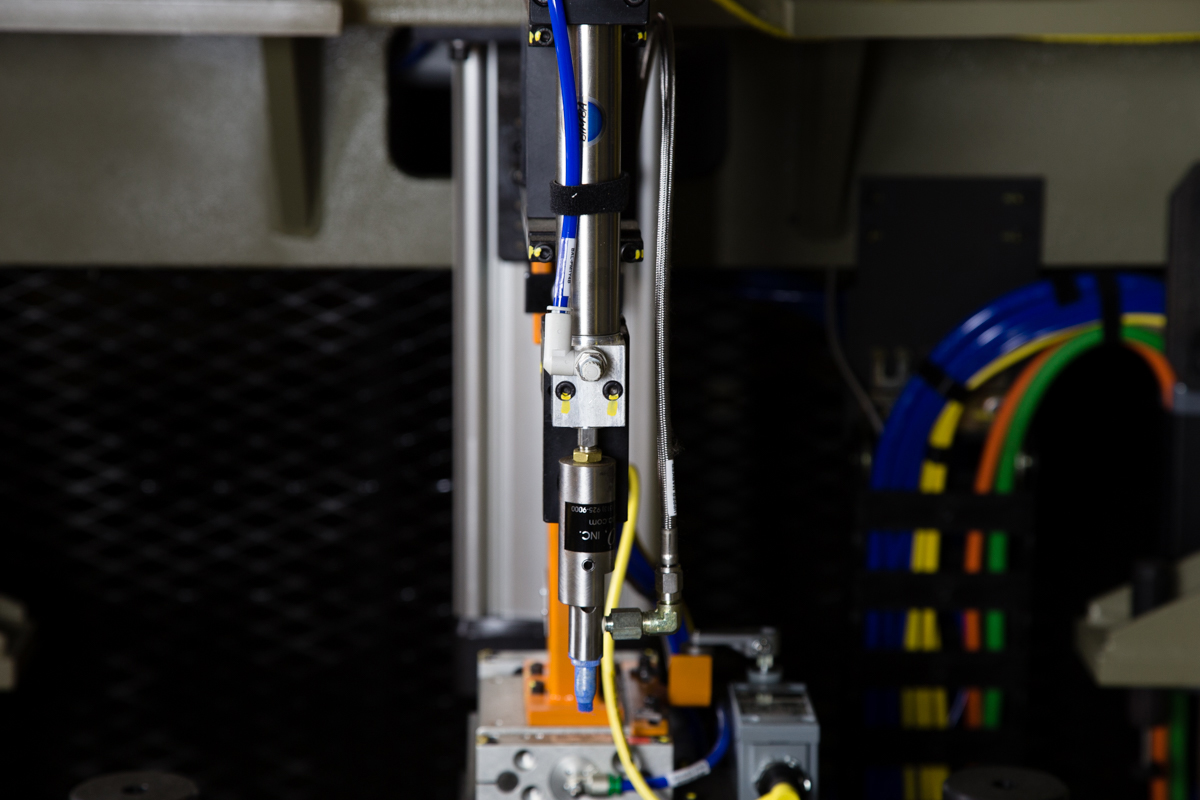

- Marking Options

- Water solvent spray markers, different colors for each plane

- Grease markers, different colors for each plane

- Tire Assembly Turnover

- Weight Stations - Ergonomic matrix of wheel weights. Multiple tier units available for weight material and style varience

- Error Proofing - pilot lights for proper selection of weight. Lights can be provided to indicate weight only or to indicate the weight and style required.

- WWAT-1650 Wheel Weight Apply Tool, used to apply stick on weights to wheels.

- Dominion Vision for plant broadcast